DN150 wide range flexible gibault joints ductile cast iron DI

universal coupling for PVC pipes

Product Introduction

Universal couplings and flange joints, suitable for DN40-DN600

specifications, steel pipes, ductile iron pipes and plastic pipes

with grades PN6, PN10 and PN16. It has the ability to connect to

different kinds of pipes. It is mainly used to absorb axial

displacement, withstand axial pressure and thrust within the

allowable displacement range, and loosen the pipeline connection.

Features

1. Earthquake-resistant, impact-resistant, noise-reducing

2. Reduce the weight of the pipeline

3. Save pipeline space

4. Cost-effective

5. Easy maintenance

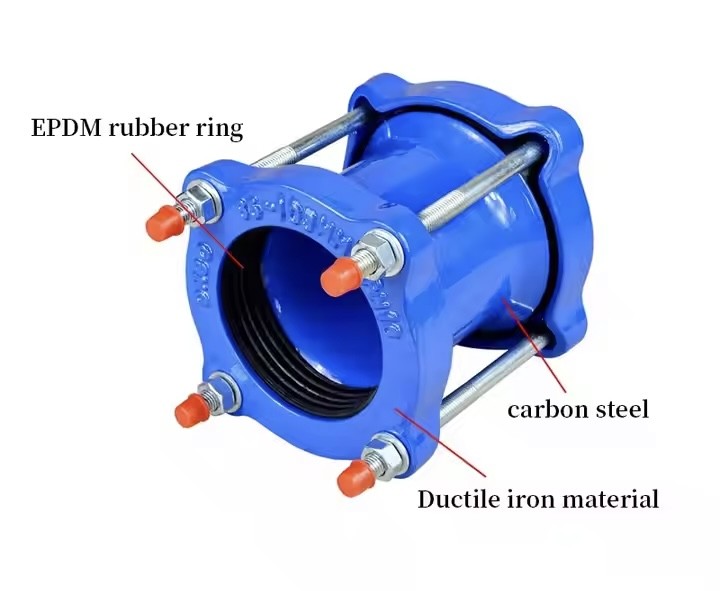

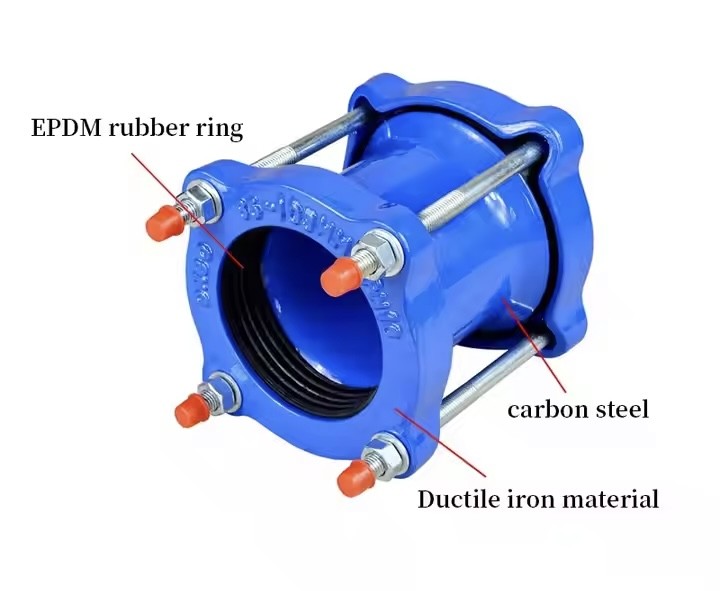

Product material

1. The pipe material is: Cast iron pipe, steel pipe, PVC/PE pipe

2. Coating: Support customization

3. Rubber ring material: EPDM, nitrile rubber, etc

4. Bolt material: 4.8 grade electro-galvanized, 8.8 grade hot-dip galvanized,

SS304,SS316 etc

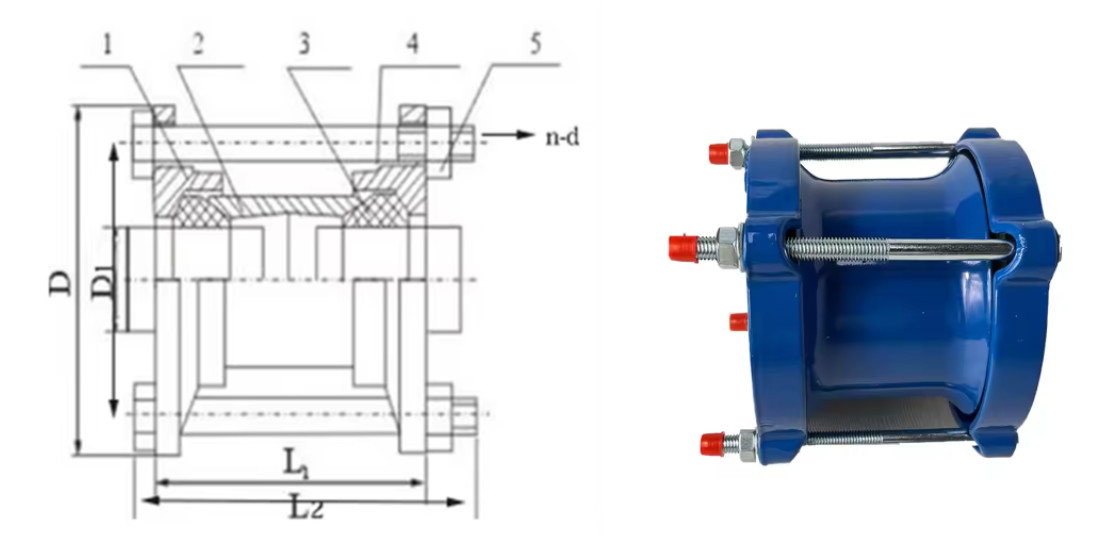

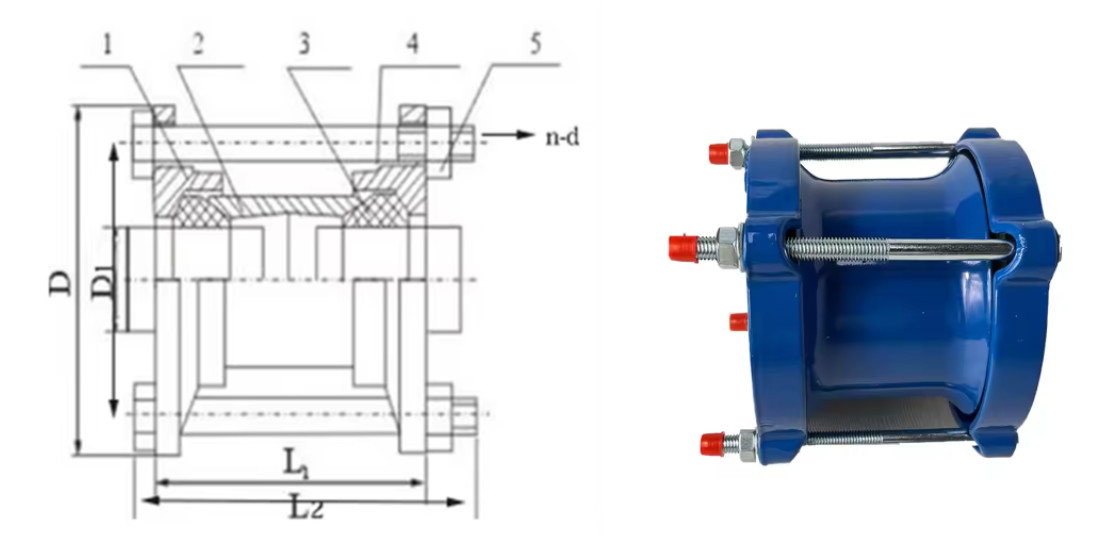

Product parameters

| DN | DW external diameter | extermal dimension | N-Th |

| Length | D | 0.25-1.6Mpa | 2.5-6.4Mpa |

| L1 | L |

| 65 | 76 | 180 | 208 | 155 | 4-M12 | 4-M12 |

| 80 | 89 | 165 |

| 100 | 108 | 195 |

| 100 | 114 | 195 |

| 125 | 133 | 225 |

| 125 | 140 | 225 | 4-M16 |

| 150 | 159 | 220 | 225 | 4-M16 | 6-M16 |

| 150 | 168 | 225 |

| 200 | 219 | 310 |

| 225 | 245 | 335 |

| 250 | 273 | 223 | 375 | 6-M20 | 8-M20 |

Tips:The above data is only part of the data, if you need a special

size, please contact us.

Installation steps and precautions for the product

1. Inspection and preparation: Before installation, the model, specification and pipeline

configuration of the compensation joint should be checked to ensure

that the design requirements are met. Remove the protective cover

and rinse it with it fully open.

2. Pipeline cleaning: Clean the pipeline to ensure that the pipeline and joints are

clean and free of impurities. At the same time, it is also

necessary to check the model and specification of the compensation

joint to ensure that it meets the requirements of the pipeline.

3. Installation position: Install the compensating joint on the pipeline in the horizontal

or vertical direction, and ensure that the pipeline near the

installation point should not sag or be affected by external force.

4. Connecting bolts: Use the specified torque to cross-tighten the flange connecting

bolts to ensure that the compensation joint is closely connected to

the pipeline.

5. Adjust the length: Adjust the connection length between the two ends of the product

and the flange to ensure that the compensating joint can absorb the

thermal expansion and contraction and vibration of the pipeline.

6.Whole machine test: The whole machine is tested according to the specified signal to

prevent vibration caused by transportation, and can be installed

only after passing the test.

7. Regular inspection and maintenance: In order to ensure that the compensation joint can work stably for

a long time, regular inspection is required. Generally speaking, it

is recommended to check once every six months, mainly to check

whether the displacement and rebound amount of the compensation

joint are normal. If any problems are found, they need to be dealt

with promptly.

Inventory display

Product Composition